Thank you for Subscribing to Agri Business Review Weekly Brief

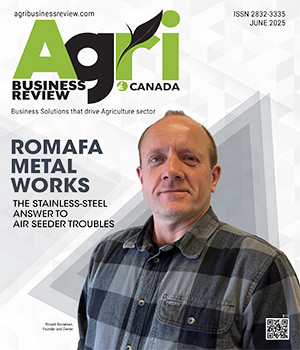

Agri Business Review: Specials Magazine

Great brands don’t just happen. They grow from trust, thrive on innovation and are shaped by the voices of everyday users. Romafa Metal Works' story best exemplifies this claim. What started as a small single-man welding, custom design and repair workshop in 2012 is now one of the premier producers of air-seeder parts in North America. The company's growth was fueled by a simple yet powerful approach — listening to clients. “Since day one, we have collaborated closely with dealers and farmers, carefully listening to their insights and integrating their ideas into our products,” says Ronald Kornelsen, founder and owner. “Even though we have technical education and engineers on the floor, we still think that the farmer handling the product knows a lot more than anyone else." The Idea that Changed Everything Romafa’s first-ever venture into designing and building an air seeder part is a perfect example of how this philosophy plays out in the real world. As word spread about Kornelsen's skill in repairing farm machinery, a local farmer approached him with an unusual request. He wanted a stainless steel cart. His seeder was corroding and he wanted to rebuild the cart using stainless steel. The project was a first of its kind, but Kornelsen leaned on his years of experience and design expertise to craft a solution. The solution's success quickly gained attention and more farmers dealing with similar corrosion issues sought his help. The problem was widespread. Most air seeders were made of mild steel, which couldn't withstand contact with fertilizers. Since these parts are only painted externally, internal corrosion often goes unnoticed until holes form. This leads to air leaks and reduces seeding quality. Romafa resolves this issue by using 304 stainless steel, eliminating corrosion and extending equipment lifespan nearly fivefold, providing farmers with a long-term, reliable solution. Soon, demand outpaced capacity and even major equipment dealers took notice, reaching out for parts. Romafa’s hands-on approach and commitment to solving real-world problems set the company on a rapid growth trajectory.

Top Greenhouse Manufacturer in Canada 2025

This company stood its ground, never detracting from the set path since 1986, earning a loyal base of customer that appreciate its commitment to quality and no-compromise mindset. Specializing in designing and manufacturing durable greenhouses, it offers a full range of models that blend indoor agriculture with permanent building structures. These stick-builds are stronger than most, enabling taller greenhouses that outperform budget options. “The extra height in our structures brings a world of difference in plant growth and climate control in ways that more temporary or budget-focused solutions simply can't match,” says Patrick Gelineau, GM. Even with their larger dimensions, DeCloet’s structures always comply with building codes, whether or not permits are required. The commitment to providing the best growth environment for plants defines its work. When conceptualizing a greenhouse, DeCloet offers standard heights of up to 16 feet under the gutter for gutter-connected builds and custom projects reaching up to 26 feet. The extra height creates a different environment for plants, with reduced humidity, better ventilation and more consistency in the internal climate that’s far more conducive to their growth. Once a customer decides to invest in these long-term benefits, DeCloet starts with a consultative client engagement. Instead of jumping to pricing, the team dives into each SOP, tailoring solutions to fit. From double poly roofs and Venlo glass systems to Grow Max models, cold frames, or Norfolks, each build is designed for optimal growth. The company also delivers installations, heating, ventilation, bench systems, wide-span buildings, and full aftersales support. Production growers, nurseries, and retail centers across North America use these solutions. It also produces widespan buildings for headhouses and the mining sector. To maintain service quality and retain hard-earned expertise, DeCloet overhauled its manufacturing to cut down on seasonality. Shifting from a reactive model to one powered by forecasting and quote tracking, team DeCloet now recognizes patterns to build inventory during slower periods while ensuring smooth project flow. Lean manufacturing has freed up resources that are invested back in the industry—something that didn’t happen before. The result is a more stable workflow, lower employee turnover, and a skilled team that keeps improving. These capabilities came in handy for a customer in western Michigan. They needed a sizeable retail greenhouse with better ventilation than standard models. DeCloet Greenhouse developed the 42-foot triple-peak double poly gutter connect greenhouse in response. The first three acres were built in 2011, and steady expansions over the years brought the facility to nine acres by 2023.

Top Agricultural Drone Services in Canada 2025

Modern agriculture is on the brink of a new era, where data drives value and shapes a better future. As food systems grow more complex and climate challenges intensify, the need for high-resolution, field-level intelligence has never been more critical. Enter Terralynx. The company provides laser-guided vision and data-driven insights that go far beyond simple aerial snapshots. It captures multi-layered environmental data, ranging from plant health indicators to soil elevation and moisture trends, allowing stakeholders to understand subtle shifts in crop behavior, anticipate drainage issues, and plan interventions with surgical precision. It’s not just about seeing the land—it’s about decoding it. Formerly known as TerraNova UAV, Terralynx has evolved far beyond its origins in drone technology. What began as a direct-to-farmer solution has transformed into a comprehensive intelligence platform. Today, it partners with agribusinesses, researchers, and government agencies, offering powerful tools to guide smarter, more sustainable land management at every level. “We’re not just about drones anymore; they’ve become a tool. Terralynx is about delivering high-resolution, data-driven intelligence that helps make smarter, more sustainable decisions. The farmer remains at the center—as the end user who benefits from it all,” says Andres Hurtado, founder and CEO of Terralynx. Technology with a Purpose From rising climate volatility to the increased demand for sustainable food production, modern land management faces growing complexity. Farmers and agribusinesses need to detect crop issues before they escalate, understand water movement through fields, and manage topography for maximum efficiency and minimal erosion. Municipalities and engineers require highly accurate landscape modeling to prevent flooding and design effective drainage systems. Whether identifying early plant stress, tracking seasonal crop behavior, mapping field elevation, or analyzing long-term trends across farmland, the need for timely, high-resolution data is at an all-time high.

CXO INSIGHTS

Improving Precision Agriculture through Cloud Based AI and ML

Enrique Leon, Director, Cloud Services, Florida Crystals, ASR

Harnessing the Power for Analytics for Agriculture - Predictive Models

Caroline Morissette, VP McDonald's Business Unit (MBU) and Commercial Data & Analytics, and Soma Muruganandam, Director Global Ag Data Center, McCain Foods

Advancing Agriculture: Sustainable Practices from the Field, to the Farm, to the Planet

Rich Burres, Director of Ag Sustainability, Lamb Weston

Cultivating Sustainability: The Vital Role of Farmers in Regenerative Agriculture

Michelle French, Senior Director of Global Sustainability Programs, ADM

From Lab to Plate: How Are Probiotics Added to Food?

Camille Binachon, Marketing Group Manager, Lallemand

Bridging Science, Business and Innovation for a Healthier Future

Jeff Moore, Global Director R&D Data Science and Computational Creativity, McCormick & Company

Embedding Sustainability into Agricultural Operations

Andrea Fogliato, Project Manager, Sustainable Agriculture, Pernod Ricard

IN FOCUS

EDITORIAL

Fresh Ideas Powering Canada’s Agricultural Rise

Greenhouse technology in Canada has evolved into a cornerstone of yearround crop production. Modern greenhouses combine energy-efficient materials with intelligent climate control systems, allowing growers to extend growing seasons and produce fresh, local food regardless of harsh weather conditions. This shift strengthens food security and reduces agriculture's environmental footprint, promoting sustainability at every stage.

Stainless steel air seeder parts, engineered to withstand Canada’s diverse and often demanding agricultural environments, are crucial for supporting field operations. Their durability ensures that seeding equipment performs consistently, maximizing seed placement accuracy and optimizing crop emergence.

The integration of agricultural drone services further accelerates the industry’s transformation. Drones provide farmers with real-time aerial data on crop health, soil moisture, and pest presence, enabling farmers to make faster, more informed decisions and optimize every stage of cultivation. The ability to monitor vast fields quickly and accurately ties back to greenhouse operations and seeding processes, creating a more connected, data-driven agricultural ecosystem.

Together, these advancements illustrate how Canadian agriculture in 2025 is moving toward a future where sustainability, resilience, and innovation work hand in hand. By leveraging smart infrastructure, robust equipment, and intelligent technology, the industry is better equipped than ever to meet the challenges of tomorrow while nurturing the land that feeds the nation.

In this edition, we explore how advancements in Canadian agriculture collectively transform farming practices and support growers at every stage of the production cycle. The magazine features companies like Romafa Metal Works a leading manufacturer of high-quality stainless steel airseeder parts.

We also present insights from expert CXOs like Paul Bonnett, Senior Director of Agronomy & Environmental Sciences (AES), Nutrien Ag Solutions and Ruohan Liu, Director, Digital Solutions for Sustainability, Agriculture and Ventures at PepsiCo, who offer their opinions on the currently used business practices. We hope these valuable insights from industry leaders and solutions and services from firms featured in this edition will assist you in making informed decisions for your businesses.

Let us know your thoughts.